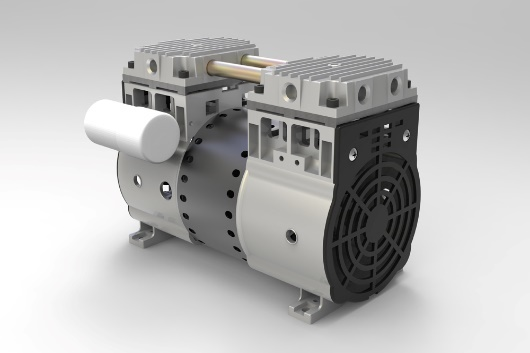

Product Description

Scope of application:

Using for Pushing Pneumatic Nail Gun, Air Screw , Spray Painting Gun to work, also use to miniature instrument, blowing dust, Air inflation for small car and so on.

Product Feature:

- High Power, high efficiency, low energy, high reliability.

- Piston Ring: New ECO circle, low friction coefficient, Auto lubricating system.

- Cylinder Liner: Surface hardening, deplete hardness, Accelerate the heat transfer, long using time.

- Suction and exhaust valve: Using advanced foreign technology.

- Multiple Pressure: Overload protection

Oilless Air Compressor Featuers:

1.Super Silent

Super low noise.The output air pressure is stable without fluctuations, reducing noise pollution.

2. Safety

If the voltage or current cause the machine overheat, it will automatically shut down to protect from burnout.

3. Automatic control

Pressure switch automatically controls the start and stop of the machine.

4. Adjustable air pressure

The air pressure can be adjusted to meet the needs of different equipment usage.

5. Save human power

Switch on the air compressor can work normally & automatically. It is easy to operate and does not need human to be on duty.

6. Easy maintenance

No need to add any lubricant, easy maintenance after purchase.

Parts Features

1.Heavy cast iron body: heavy load, long stroke, low fuel consumption, low noise

2.Cylinder: made of high-grade cast iron, strength, good lubricity, wall by the fine honing, wear-resistant, durable

3.Piston ring: good elasticity, excellent wear resistance, low oil consumption, not easy to make the valve group carbon deposition and loss of oil to burn the crankshaft and connecting rod.

4.The crankshaft, connecting rod, piston: well balanced, wear resistance, high strength, smooth running balance.

5.High reliable and durable valve; strong aluminum alloy body, light and heat.

6.The motor provides reliable power, low voltage start up and running performance strong fan cooled motor and body; special shock proof design.

7.Double nozzles, were used to direct the exhaust and pressure exhaust; pressure switch with push button, safe and convenient

8.Oil free,silent,protect-environment,suitable for dental use.

Frequency Asked Question

1.Are you the manufacturer or trading company?

We are the manufacturer.

2.Where is your factory?

It is located in HangZhou City,ZHangZhoug Province,China.

3.What’s the terms of trade?

FOB,CFR,CIF or EXW are all acceptable.

4.What’s the terms of payment?

T/T,L/C at sight or cash.

5.What’s the lead time?

We are the manufacturer.

It is located in HangZhou City,ZHangZhoug Province,China.

FOB,CFR,CIF or EXW are all acceptable.

T/T,L/C at sight or cash.

In 15 days on receipt of deposit .

6.Do you accept sample order?

Yes,we accept.

7.What about the cost of sample?

You have to pay the freight charge.But the cost of product could be refundable,if you will purchase 1x20GP container in the future.

Yes,we accept.

You have to pay the freight charge.But the cost of product could be refundable,if you will purchase 1x20GP container in the future.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Lubrication Style: | Oil-less |

|---|---|

| Cooling System: | Air Cooling |

| Cylinder Arrangement: | Duplex Arrangement |

| Cylinder Position: | Vertical |

| Structure Type: | Open Type |

| Compress Level: | Double-Stage |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

Types of vacuum pumps

A vacuum pump is a device that draws gas molecules from a sealed volume and leaves a partial vacuum in its wake. Its job is to create a relative vacuum within a specific volume or volume. There are many types of vacuum pumps, including centrifugal, screw and diaphragm.

Forward centrifugal pump

Positive displacement centrifugal vacuum pumps are one of the most commonly used pump types in the oil and gas industry. Their efficiency is limited to a range of materials and can handle relatively high solids concentrations. However, using these pumps has some advantages over other types of pumps.

Positive displacement pumps have an enlarged cavity on the suction side and a reduced cavity on the discharge side. This makes them ideal for applications involving high viscosity fluids and high pressures. Their design makes it possible to precisely measure and control the amount of liquid pumped. Positive displacement pumps are also ideal for applications requiring precise metering.

Positive displacement pumps are superior to centrifugal pumps in several ways. They can handle higher viscosity materials than centrifuges. These pumps also operate at lower speeds than centrifugal pumps, which makes them more suitable for certain applications. Positive displacement pumps are also less prone to wear.

Positive displacement vacuum pumps operate by drawing fluid into a chamber and expanding it to a larger volume, then venting it to the atmosphere. This process happens several times per second. When maximum expansion is reached, the intake valve closes, the exhaust valve opens, and fluid is ejected. Positive displacement vacuum pumps are highly efficient and commonly used in many industries.

Self-priming centrifugal pump

Self-priming centrifugal pumps are designed with a water reservoir to help remove air from the pump. This water is then recirculated throughout the pump, allowing the pump to run without air. The water reservoir can be located above or in front of the impeller. The pump can then reserve water for the initial start.

The casing of the pump contains an increasingly larger channel forming a cavity retainer and semi-double volute. When water enters the pump through channel A, it flows back to the impeller through channels B-C. When the pump is started a second time, the water in the pump body will be recirculated back through the impeller. This recycling process happens automatically.

These pumps are available in a variety of models and materials. They feature special stainless steel castings that are corrosion and wear-resistant. They can be used in high-pressure applications and their design eliminates the need for inlet check valves and intermediate valves. They can also be equipped with long intake pipes, which do not require activation.

Self-priming centrifugal pumps are designed to run on their own, but there are some limitations. They cannot operate without a liquid source. A foot valve or external liquid source can help you start the self-priming pump.

Screw Pump

The mechanical and thermal characteristics of a screw vacuum pump are critical to its operation. They feature a small gap between the rotor and stator to minimize backflow and thermal growth. Temperature is a key factor in their performance, so they have an internal cooling system that uses water that circulates through the pump’s stator channels. The pump is equipped with a thermostatically controlled valve to regulate the water flow. Also includes a thermostatic switch for thermal control.

Screw vacuum pumps work by trapping gas in the space between the rotor and the housing. The gas is then moved to the exhaust port, where it is expelled at atmospheric pressure. The tapered discharge end of the screw further reduces the volume of gas trapped in the chamber. These two factors allow the pump to work efficiently and safely.

Screw vacuum pumps are designed for a variety of applications. In some applications, the pump needs to operate at very low pressures, such as when pumping large volumes of air. For this application, the SCREWLINE SP pump is ideal. Their low discharge temperature and direct pumping path ensure industrial process uptime. These pumps also feature non-contact shaft seals to reduce mechanical wear. Additionally, they feature a special cantilever bearing arrangement to eliminate potential sources of bearing failure and lubrication contamination.

Screw vacuum pumps use an air-cooled screw to generate a vacuum. They are compact, and clean, and have a remote monitoring system with built-in intelligence. By using the app, users can monitor pump performance remotely.

Diaphragm Pump

Diaphragm vacuum pumps are one of the most common types of vacuum pumps found in laboratories and manufacturing facilities. The diaphragm is an elastomeric membrane held in place around the outer diameter. While it is not possible to seal a diaphragm vacuum pump, there are ways to alleviate the problems associated with this design.

Diaphragm vacuum pumps are versatile and can be used in a variety of clean vacuum applications. These pumps are commercially available with a built-in valve system, but they can also be modified to include one. Because diaphragm pumps are so versatile, it’s important to choose the right type for the job. Understanding how pumps work will help you match the right pump to the right application.

Diaphragm vacuum pumps offer a wide range of advantages, including an extremely long service life. Most diaphragm pumps can last up to ten thousand hours. However, they may be inefficient for processes that require deep vacuum, in which case alternative technologies may be required. Additionally, due to the physics of diaphragm pumps, the size of these pumps may be limited. Also, they are not suitable for high-speed pumping.

Diaphragm vacuum pumps are a versatile subset of laboratory pumps. They are popular for their oil-free construction and low maintenance operation. They are available in a variety of styles and have many optional features. In addition to low maintenance operation, they are chemically resistant and can be used with a variety of sample types. However, diaphragm pumps tend to have lower displacements than other vacuum pumps.

Atmospheric pressure is a key factor in a vacuum pump system

Atmospheric pressure is the pressure created by the collision of air molecules. The more they collide, the greater the pressure. This applies to pure gases and mixtures. When you measure atmospheric pressure, the pressure gauge reads about 14.7 psia. The higher the pressure, the greater the force on the gas molecules.

The gas entering the vacuum pump system is below atmospheric pressure and may contain entrained liquids. The mechanism of this process can be explained by molecular kinetic energy theory. The theory assumes that gas molecules in the atmosphere have high velocities. The resulting gas molecules will then start moving in random directions, colliding with each other and creating pressure on the walls of the vacuum vessel.

Atmospheric pressure is a critical factor in a vacuum pump system. A vacuum pump system is useless without proper atmospheric pressure measurement. The pressure in the atmosphere is the total pressure of all gases, including nitrogen and oxygen. Using total pressure instead of partial pressure can cause problems. The thermal conductivity of various gases varies widely, so working at full pressure can be dangerous.

When choosing a vacuum pump, consider its operating range. Some pumps operate at low atmospheric pressure, while others are designed to operate at high or ultra-high pressure. Different types of pumps employ different technologies that enhance their unique advantages.

The screw pump is less efficient in pumping gases with smaller molecular weight

Vacuuming requires a high-quality pump. This type of pump must be able to pump gas of high purity and very low pressure. Screw pumps can be used in laboratory applications and are more efficient when pumping small molecular weight gases. Chemical resistance is critical to pump life. Chemical resistant materials are also available. Chemically resistant wetted materials minimize wear.

Gear pumps are more efficient than screw pumps, but are less efficient when pumping lower molecular weight gases. Gear pumps also require a larger motor to achieve the same pumping capacity. Compared to gear pumps, progressive cavity pumps also have lower noise levels and longer service life. In addition, gear pumps have a large footprint and are not suitable for tight spaces.

Progressive cavity pumps have two or three screws and a housing and side cover. They are also equipped with gears and bearings. Their mechanical design allows them to operate in high pressure environments with extremely low noise. The progressive cavity pump is a versatile pump that can be used in a variety of applications.

Dry screw compressors have different aspect ratios and can operate at high and low pressures. The maximum allowable differential pressure for screw compressors ranges from 0.4 MPa for 3/5 rotors to 1.5 MPa for 4/6 rotors. These numbers need to be determined on a case-by-case basis.

editor by CX 2024-04-03

China manufacturer Industrial Screw Piston AC Silent Oilless Oil Free Vacuum Low Noise Copper Home Small Highly Portable Rotary Part Mini Air Compressor Pump with high quality

Product Description

Scope of application:

Using for Pushing Pneumatic Nail Gun, Air Screw , Spray Painting Gun to work, also use to miniature instrument, blowing dust, Air inflation for small car and so on.

Product Feature:

- High Power, high efficiency, low energy, high reliability.

- Piston Ring: New ECO circle, low friction coefficient, Auto lubricating system.

- Cylinder Liner: Surface hardening, deplete hardness, Accelerate the heat transfer, long using time.

- Suction and exhaust valve: Using advanced foreign technology.

- Multiple Pressure: Overload protection

Oilless Air Compressor Featuers:

1.Super Silent

Super low noise.The output air pressure is stable without fluctuations, reducing noise pollution.

2. Safety

If the voltage or current cause the machine overheat, it will automatically shut down to protect from burnout.

3. Automatic control

Pressure switch automatically controls the start and stop of the machine.

4. Adjustable air pressure

The air pressure can be adjusted to meet the needs of different equipment usage.

5. Save human power

Switch on the air compressor can work normally & automatically. It is easy to operate and does not need human to be on duty.

6. Easy maintenance

No need to add any lubricant, easy maintenance after purchase.

Parts Features

1.Heavy cast iron body: heavy load, long stroke, low fuel consumption, low noise

2.Cylinder: made of high-grade cast iron, strength, good lubricity, wall by the fine honing, wear-resistant, durable

3.Piston ring: good elasticity, excellent wear resistance, low oil consumption, not easy to make the valve group carbon deposition and loss of oil to burn the crankshaft and connecting rod.

4.The crankshaft, connecting rod, piston: well balanced, wear resistance, high strength, smooth running balance.

5.High reliable and durable valve; strong aluminum alloy body, light and heat.

6.The motor provides reliable power, low voltage start up and running performance strong fan cooled motor and body; special shock proof design.

7.Double nozzles, were used to direct the exhaust and pressure exhaust; pressure switch with push button, safe and convenient

8.Oil free,silent,protect-environment,suitable for dental use.

Frequency Asked Question

1.Are you the manufacturer or trading company?

We are the manufacturer.

2.Where is your factory?

It is located in HangZhou City,ZHangZhoug Province,China.

3.What’s the terms of trade?

FOB,CFR,CIF or EXW are all acceptable.

4.What’s the terms of payment?

T/T,L/C at sight or cash.

5.What’s the lead time?

We are the manufacturer.

It is located in HangZhou City,ZHangZhoug Province,China.

FOB,CFR,CIF or EXW are all acceptable.

T/T,L/C at sight or cash.

In 15 days on receipt of deposit .

6.Do you accept sample order?

Yes,we accept.

7.What about the cost of sample?

You have to pay the freight charge.But the cost of product could be refundable,if you will purchase 1x20GP container in the future.

Yes,we accept.

You have to pay the freight charge.But the cost of product could be refundable,if you will purchase 1x20GP container in the future.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Lubrication Style: | Oil-less |

|---|---|

| Cooling System: | Air Cooling |

| Cylinder Arrangement: | Duplex Arrangement |

| Cylinder Position: | Vertical |

| Structure Type: | Open Type |

| Compress Level: | Double-Stage |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How Does a Piston Vacuum Pump Work?

A piston vacuum pump, also known as a reciprocating vacuum pump, operates using a piston mechanism to create a vacuum. Here’s a detailed explanation of its working principle:

1. Piston and Cylinder Assembly:

– A piston vacuum pump consists of a piston and cylinder assembly.

– The piston is a movable component that fits inside the cylinder and creates a seal between the piston and cylinder walls.

2. Intake and Exhaust Valves:

– The cylinder has two valves: an intake valve and an exhaust valve.

– The intake valve allows gas or air to enter the cylinder during the suction stroke, while the exhaust valve allows the expelled gas to exit during the compression stroke.

3. Suction Stroke:

– During the suction stroke, the piston moves downward, creating a vacuum within the cylinder.

– As the piston moves down, the intake valve opens, allowing gas or air from the system being evacuated to enter the cylinder.

– The volume within the cylinder increases, causing a decrease in pressure and the creation of a partial vacuum.

4. Compression Stroke:

– After the suction stroke, the piston moves upward during the compression stroke.

– As the piston moves up, the intake valve closes, preventing backflow of gas into the evacuated system.

– Simultaneously, the exhaust valve opens, allowing the gas trapped in the cylinder to be expelled.

– The upward movement of the piston reduces the volume within the cylinder, compressing the gas and increasing its pressure.

5. Expulsion of Gas:

– Once the compression stroke is complete, the gas is expelled through the exhaust valve.

– The exhaust valve then closes, ready for the next suction stroke.

– This process of alternating suction and compression strokes continues, gradually reducing the pressure within the evacuated system.

6. Lubrication:

– Piston vacuum pumps require lubrication for smooth operation and to maintain the airtight seal between the piston and cylinder walls.

– Lubricating oil is often introduced into the cylinder to provide lubrication and help maintain the seal.

– The oil also helps to cool the pump by dissipating heat generated during operation.

7. Applications:

– Piston vacuum pumps are commonly used in applications where high vacuum levels and low flow rates are required.

– They are suitable for processes such as laboratory work, vacuum drying, vacuum filtration, and other applications that require moderate vacuum levels.

In summary, a piston vacuum pump operates by creating a vacuum through the reciprocating motion of a piston within a cylinder. The suction stroke creates a vacuum by lowering the pressure within the cylinder, while the compression stroke expels the gas and increases its pressure. This cyclic process continues, gradually reducing the pressure within the system being evacuated. Piston vacuum pumps are commonly used in various applications that require moderate vacuum levels and low flow rates.

What Is the Energy Efficiency of Piston Vacuum Pumps?

The energy efficiency of piston vacuum pumps can vary depending on several factors. Here’s a detailed explanation:

1. Design and Technology:

– The design and technology used in piston vacuum pumps can significantly influence their energy efficiency.

– Modern piston pump designs often incorporate features such as optimized valve systems, reduced internal leakage, and improved sealing mechanisms to enhance efficiency.

– Advancements in materials and manufacturing techniques have also contributed to more efficient piston pump designs.

2. Motor Efficiency:

– The motor driving the piston pump plays a crucial role in overall energy efficiency.

– High-efficiency motors, such as those adhering to energy efficiency standards like NEMA Premium or IE3, can significantly improve the energy efficiency of the pump.

– Proper motor sizing and matching to the pump’s load requirements are also important to maximize efficiency.

3. Control Systems:

– The use of advanced control systems can optimize the energy consumption of piston vacuum pumps.

– Variable frequency drives (VFDs) or speed control systems can adjust the pump’s operating speed based on the demand, reducing energy consumption during periods of lower demand.

– Smart control algorithms and sensors can also help optimize the pump’s performance and energy efficiency.

4. System Design and Integration:

– The overall system design and integration of the piston vacuum pump within the application can impact energy efficiency.

– Proper sizing and selection of the pump based on the specific application requirements can ensure that the pump operates within its optimal efficiency range.

– Efficient piping and ducting design, as well as minimizing pressure losses and leaks, can further improve the overall energy efficiency of the system.

5. Load Profile and Operating Conditions:

– The load profile and operating conditions of the piston vacuum pump have a significant impact on energy consumption.

– Higher vacuum levels or flow rates may require more energy to be supplied by the pump.

– Operating the pump continuously at maximum capacity may lead to higher energy consumption compared to intermittent or variable load conditions.

– It’s important to evaluate the specific operating requirements and adjust the pump’s operation accordingly to optimize energy efficiency.

6. Comparing Efficiency Ratings:

– When comparing the energy efficiency of different piston vacuum pumps, it can be helpful to look for efficiency ratings or specifications provided by the manufacturer.

– Some manufacturers provide efficiency data or performance curves indicating the pump’s energy consumption at various operating points.

– These ratings can assist in selecting a pump that meets the desired energy efficiency requirements.

In summary, the energy efficiency of piston vacuum pumps can be influenced by factors such as design and technology, motor efficiency, control systems, system design and integration, load profile, and operating conditions. Considering these factors and evaluating efficiency ratings can help in selecting an energy-efficient piston vacuum pump for a specific application.

What Is the Role of Lubrication in Piston Vacuum Pump Operation?

Lubrication plays a crucial role in the operation of a piston vacuum pump. Here’s a detailed explanation:

1. Reduction of Friction:

– Lubrication is essential for reducing friction between moving parts within the pump.

– In a piston vacuum pump, the piston moves up and down inside the cylinder, and lubrication helps to minimize the friction between the piston rings and the cylinder wall.

– By reducing friction, lubrication prevents excessive wear and heat generation, ensuring smooth and efficient operation of the pump.

2. Sealing and Leakage Prevention:

– Lubrication helps to maintain proper sealing between the piston rings and the cylinder wall.

– The lubricating oil forms a thin film between these surfaces, creating a barrier that prevents gas leakage during the compression and vacuum creation process.

– Effective sealing is crucial for maintaining the desired vacuum level and preventing air or gas from entering the pump.

3. Cooling and Heat Dissipation:

– Piston vacuum pumps generate heat during operation, particularly due to the compression of gases.

– Lubricating oil helps in dissipating the heat generated, preventing the pump from overheating.

– The oil absorbs heat from the pump’s internal components and transfers it to the pump’s housing or cooling system.

– Proper cooling and heat dissipation contribute to the pump’s overall performance and prevent damage due to excessive heat buildup.

4. Contaminant Removal:

– Lubrication also aids in removing contaminants or particles that may enter the pump.

– The oil acts as a carrier, trapping and carrying away small particles or debris that could potentially damage the pump’s components.

– The oil passes through filters that help to remove these contaminants, keeping the pump’s internal parts clean and functioning properly.

5. Corrosion Prevention:

– Some lubricating oils contain additives that provide corrosion protection.

– These additives form a protective film on the pump’s internal surfaces, preventing corrosion caused by exposure to moisture or corrosive gases.

– Corrosion prevention is crucial for maintaining the pump’s performance, extending its lifespan, and minimizing the need for repairs or component replacement.

6. Proper Lubrication Selection:

– Selecting the appropriate lubricating oil is essential for the proper functioning of a piston vacuum pump.

– Different pump models and manufacturers may recommend specific oil types or viscosities to ensure optimal performance and longevity.

– It is crucial to follow the manufacturer’s guidelines regarding oil selection, oil level, and oil change intervals.

In summary, lubrication plays a vital role in piston vacuum pump operation by reducing friction, maintaining proper sealing, dissipating heat, removing contaminants, and preventing corrosion. Proper lubrication selection and adherence to manufacturer’s guidelines are crucial for ensuring the pump’s efficient and reliable performance.

editor by CX 2024-03-23

China wholesaler 750W Oil Free Piston Vacuum Pump Air Compression Pump Small Air Compressor Cn Zhe Made in China Silent Oil Pump for Packaging Machinery with Best Sales

Product Description

|

Model |

BST850AFZ/BSZ |

|

Voltage/frequency (V/Hz) |

220-240V/50Hz 100v-120v/60Hz |

|

Input power(W) |

≤550 |

|

Speed (r/min) |

≥1350 1650 |

|

Primary vacuumKPa |

-93KPa |

|

Secondary vacuumKPa |

-98KPa |

|

Restart pressure (KPa) |

0KPa |

|

Rated volume flow (m3/h) |

≥12m3/h @0KPa; |

|

Noise dB(A) |

≤62dB(A) |

|

Ambient temperature ºC |

-5-40 ºC |

|

Insulation Class |

F |

|

Cold insulation resistance (MΩ) |

≥100MΩ |

|

Voltage resistance |

1500V/50Hz 1min(No breakdown) |

|

Thermal protector |

Automatic reset 135±5ºC |

|

Capacitance (μF) |

25μF±5% 75μF±5% |

|

Net weight (Kg) |

10.5Kg |

|

Installation Dimensions (mm) |

223.2×88.9 mm(4XM6) |

|

External Dimensions (mm) |

268.8*128*214.7mm |

| Typical application | |

| Respirator (ventilator) | oxygenerator |

| Disinfectant sprayer | Blood analyzer |

| Clinical aspirator | Dialysis / hemodialysis |

| Dental vacuum drying oven | Air suspension system |

| Vending machines / coffee blenders and coffee machines | Massage chair |

| Chromatographic analyzer | Teaching instrument platform |

| On board access control system | Airborne oxygen generator |

Why choose CZPT air compressor

1. It saves 10-30% energy than the air compressor produced by ordinary manufacturers.

2. It is widely used in medical oxygen generator and ventilator .

3. A large number of high-speed train and automobile application cases, supporting – 41 to 70 ºC, 0-6000 CZPT above sea level .

4. Medium and high-end quality, with more than 7000 hours of trouble free operation for conventional products and more than 15000 hours of trouble free operation for high-end products.

5. Simple operation, convenient maintenance and remote guidance.

6. Faster delivery time, generally completed within 25 days within 1000 PCs.

Machine Parts

Name: Motor

Brand: COMBESTAIR

Original: China

1.The coil adopts the fine pure copper enameled wire, and the rotor adopts the famous brand silicon steel sheet such as ZheJiang baosteel.

2.The customer can choose the insulation grade B or F motor according to What he wants.

3.The motor has a built-in thermal protector, which can select external heat sensor.

4.Voltage from AC100V ~120V, 200V ~240V, 50Hz / 60Hz, DC6V~200V optional ; AC motor can choose double voltage double frequency ; DC Motor can choose the control of the infinitely variable speed.

Machine Parts

Name: Bearing

Brand: ERB , CZPT , NSK

Original: China ect.

1.Standard products choose the special bearing ‘ERB’ in oil-free compressor, and the environment temperature tolerance from -50ºC to 180 ºC . Ensure no fault operation for 20,000 hours.

2.Customers can select TPI, NSK and other imported bearings according to the working condition.

Machine Parts

Name: Valve plates

Brand: SANDVIK

Original: Sweden

1.Custom the valve steel of Sweden SANDVIK; Good flexibility and long durability.

2.Thickness from 0.08mm to 1.2mm, suitable for maximum pressure from 0.8 MPa to 1.2 MPa.

Machine Parts

Name: Piston ring

Brand: COMBESTAIR-OEM , Saint-Gobain

Original: China , France

1.Using domestic famous brand–Polytetrafluoroethylene composite material; Wear-resistant high temperature; Ensure more than 10,000 hours of service life.

2.High-end products: you can choose the ST.gobain’s piston ring from the American import.

| serial number |

Code number | Name and specification | Quantity | Material | Note |

| 1 | 212571109 | Fan cover | 2 | Reinforced nylon 1571 | |

| 2 | 212571106 | Left fan | 1 | Reinforced nylon 1571 | |

| 3 | 212571101 | Left box | 1 | Die-cast aluminum alloy YL104 | |

| 4 | 212571301 | Connecting rod | 2 | Die-cast aluminum alloy YL104 | |

| 5 | 212571304 | Piston cup | 2 | PHB filled PTFE | |

| 6 | 212571302 | Clamp | 2 | Die-cast aluminum alloy YL102 | |

| 7 | 7050616 | Screw of cross head | 2 | Carbon structural steel of cold heading | M6•16 |

| 8 | 212571501 | Air cylinder | 2 | Thin wall pipe of aluninun alloy 6A02T4 | |

| 9 | 17103 | Seal ring of Cylinder | 2 | Silicone rubber | |

| 10 | 212571417 | Sealing ring of cylinder cover | 2 | Silicone rubber | |

| 11 | 212571401 | Cylinder head | 2 | Die-cast aluminum alloy YL102 | |

| 12 | 7571525 | Screw of inner hexagon Cylinder head | 12 | M5•25 | |

| 13 | 17113 | Sealing ring of connecting pipe | 4 | Silicong rubber | |

| 14 | 212571801 | Connecting pipe | 2 | Aluminum and aluminum alloy connecting rod LY12 | |

| 15 | 7100406 | Screw of Cross head | 4 | 1Cr13N19 | M4•6 |

| 16 | 212571409 | Limit block | 2 | Die-cast aluminum alloy YL102 | |

| 17 | 000402.2 | Air outlet valve | 2 | 7Cr27 quenching steel belt of The Swedish sandvik | |

| 18 | 212571403 | valve | 2 | Die-cast aluminum alloy YL102 | |

| 19 | 212571404 | Air inlet valve | 2 | 7Cr27 quenching steel belt of The Swedish sandvik | |

| 20 | 212571406 | Metal gasket | 2 | Stainless steel plate of heat and acidresistance | |

| 21 | 212571107 | Right fan | 1 | Reinforced nylon 1571 | |

| 22 | 212571201 | Crank | 2 | Gray castiron H20-40 | |

| 23 | 14040 | Bearing 6006-2Z | 2 | ||

| 24 | 70305 | Tighten screw of inner hexagon flat end | 2 | M8•8 | |

| 25 | 7571520 | Screw of inner hexagon Cylinder head | 2 | M5•20 | |

| 26 | 212571102 | Right box | 1 | Die-cast aluminum alloy YL104 | |

| 27 | 6P-4 | Lead protective ring | 1 | ||

| 28 | 7095712-211 | Hexagon head bolt | 2 | Carbon structural steel of cold heading | M5•152 |

| 29 | 715710-211 | Screw of Cross head | 2 | Carbon structural steel of cold heading | M5•120 |

| 30 | 16602 | Light spring washer | 4 | ø5 | |

| 31 | 212571600 | Stator | 1 | ||

| 32 | 70305 | Lock nut of hexagon flange faces | 2 | ||

| 33 | 212571700 | Rotor | 1 | ||

| 34 | 14032 | Bearing 6203-2Z | 2 |

FAQ

Q1: Are you factory or trade company?

A1: We are factory.

Q2: What the exactly address of your factory?

A2: Our factory is located in Linbei industrial area No.30 HangZhou City of ZHangZhoug Province, China

Q3: Warranty terms of your machine?

A3: Two years warranty for the machine and technical support according to your needs.

Q4: Will you provide some spare parts of the machines?

A4: Yes, of course.

Q5: How long will you take to arrange production?

A5: Generally, 1000 pcs can be delivered within 25 days

Q6: Can you accept OEM orders?

A6: Yes, with professional design team, OEM orders are highly welcome

Q7:Can you accept non-standard customization?

A7:We have the ability to develop new products and can customize, develop and research according to your requirements

| After-sales Service: | Remote Guided Maintenance |

|---|---|

| Warranty: | 2 Years |

| Principle: | Mixed-Flow Compressor |

| Samples: |

US$ 65/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What Are the Advantages of Using Piston Vacuum Pumps?

Piston vacuum pumps offer several advantages that make them suitable for various applications. Here’s a detailed explanation of the advantages of using piston vacuum pumps:

1. High Vacuum Levels:

– Piston vacuum pumps are capable of achieving high vacuum levels, making them suitable for applications that require deep vacuum conditions.

– They can create and maintain a vacuum in the range of millitorr (10-3 Torr) to microns (10-6 Torr).

2. Low Flow Rates:

– Piston vacuum pumps are designed to handle low flow rates efficiently.

– They are suitable for applications where a steady and controlled evacuation is required rather than high-volume pumping.

3. Compact and Portable:

– Piston vacuum pumps are relatively compact and lightweight compared to other types of vacuum pumps.

– Their compact design allows for easy installation in limited spaces or portable applications where mobility is required.

4. Oil Lubrication:

– Many piston vacuum pumps utilize oil lubrication for smooth operation and to maintain airtight seals.

– The oil lubrication also helps to cool the pump by dissipating heat generated during operation.

5. Wide Range of Applications:

– Piston vacuum pumps find applications in various industries and processes.

– They are commonly used in laboratories, research facilities, pharmaceutical production, vacuum drying, vacuum filtration, and other applications that require moderate vacuum levels and low flow rates.

6. Cost-Effective:

– Piston vacuum pumps are often more cost-effective compared to other high-vacuum pumps such as turbomolecular pumps or cryogenic pumps.

– They provide a reliable and affordable solution for achieving vacuum requirements in many applications.

7. Easy Maintenance:

– Piston vacuum pumps are relatively easy to maintain.

– Regular maintenance tasks include checking and replacing lubricating oil, inspecting and cleaning valves, and ensuring proper sealing.

– Routine maintenance helps to prolong the lifespan of the pump and maintain its performance.

8. Durability:

– Piston vacuum pumps are known for their durability and long operational life.

– They are designed to withstand continuous operation and handle demanding vacuum conditions.

– With proper care and maintenance, piston vacuum pumps can provide reliable performance over an extended period.

9. Versatility:

– Piston vacuum pumps can handle a wide range of gases, including inert gases, corrosive gases, and vapors.

– This versatility makes them suitable for diverse applications in different industries.

In summary, the advantages of using piston vacuum pumps include their ability to achieve high vacuum levels, handle low flow rates, compact and portable design, oil lubrication for smooth operation, wide range of applications, cost-effectiveness, easy maintenance, durability, and versatility. These advantages make piston vacuum pumps a popular choice in various industries where moderate vacuum levels and controlled evacuation are required.

How Do You Troubleshoot Common Issues with Piston Vacuum Pumps?

Troubleshooting common issues with piston vacuum pumps involves a systematic approach to identify and resolve problems. Here’s a detailed explanation:

1. Insufficient Vacuum Level:

– If the vacuum level achieved by the piston pump is lower than expected:

– Check for leaks: Inspect all connections, seals, and fittings for any signs of leakage. Repair or replace any damaged components.

– Verify valve operation: Ensure that the valves in the pump are functioning correctly. Clean or replace any faulty valves that may be impeding the pump’s performance.

– Check for worn piston or cylinder: Examine the piston and cylinder for signs of wear. If necessary, replace these components to restore optimal vacuum performance.

2. Excessive Noise or Vibrations:

– If the piston pump is producing excessive noise or vibrations:

– Check for misalignment: Ensure that the pump is properly aligned with its drive mechanism. Adjust or realign as necessary.

– Inspect mounting and support: Examine the pump’s mounting and support structure to ensure it is stable and secure. Reinforce or repair any weak or damaged mounts.

– Verify lubrication: Adequate lubrication is crucial for smooth pump operation. Check the lubrication system and ensure it is supplying sufficient lubricant to all necessary components.

3. Overheating:

– If the piston pump is overheating:

– Check cooling system: Inspect the cooling system, including fans, heat exchangers, and cooling fins. Clean or replace any clogged or malfunctioning cooling components.

– Verify airflow: Ensure that there is proper airflow around the pump. Remove any obstructions or debris that may be impeding the flow of cooling air.

– Evaluate operating conditions: Examine the pump’s operating conditions, such as ambient temperature and duty cycle. Adjust these factors if necessary to prevent overheating.

4. Oil Contamination:

– If there is oil contamination in the vacuum system:

– Check oil seals: Inspect the seals in the pump for any signs of damage or wear. Replace any faulty seals that may be allowing oil leakage.

– Verify oil level and quality: Ensure that the pump’s oil level is correct and that the oil is clean and free from contaminants. Replace the oil if necessary.

– Evaluate oil mist separation: If the pump is equipped with oil mist separation mechanisms, verify their effectiveness. Clean or replace any filters or separators that may be compromised.

5. Insufficient Pumping Capacity:

– If the pump is unable to meet the required pumping capacity:

– Check for blockages: Inspect the intake and exhaust ports for any blockages or obstructions. Clear any debris or foreign objects that may be impeding the pump’s operation.

– Verify valve operation: Ensure that the valves are opening and closing properly. Clean or replace any valves that may be stuck or malfunctioning.

– Evaluate motor performance: Assess the motor driving the pump for any issues such as insufficient power or improper speed. Repair or replace the motor if necessary.

6. Manufacturer’s Guidelines:

– It’s important to consult the manufacturer’s guidelines and documentation for specific troubleshooting procedures and recommendations tailored to the particular piston vacuum pump model.

– Follow the manufacturer’s instructions for routine maintenance, inspections, and any specific troubleshooting steps provided.

In summary, troubleshooting common issues with piston vacuum pumps involves steps such as checking for leaks, verifying valve operation, inspecting for wear or misalignment, ensuring proper lubrication and cooling, addressing oil contamination, clearing blockages, and evaluating motor performance. Following the manufacturer’s guidelines and documentation is essential for accurate troubleshooting and resolving problems effectively.

Can Piston Vacuum Pumps Handle Corrosive Gases or Vapors?

Piston vacuum pumps are generally not suitable for handling corrosive gases or vapors. Here’s a detailed explanation:

1. Construction Materials:

– Piston vacuum pumps are typically constructed with materials such as cast iron, aluminum, stainless steel, and various elastomers.

– While these materials offer good resistance to normal operating conditions, they may not be compatible with corrosive substances.

– Corrosive gases or vapors can attack and degrade the pump’s internal components, leading to reduced performance, increased wear, and potential failure.

2. Sealing and Contamination:

– Piston vacuum pumps rely on tight seals and clearances to maintain the vacuum and prevent leakage.

– Corrosive gases or vapors can degrade the seals and compromise their effectiveness.

– This can result in increased leakage, reduced pumping efficiency, and potential contamination of the pump and the surrounding environment.

3. Maintenance and Service:

– Handling corrosive gases or vapors requires specialized knowledge, materials, and maintenance procedures.

– The pump may need additional protective measures, such as corrosion-resistant coatings or specialized seal materials, to withstand the corrosive environment.

– Regular inspection, cleaning, and replacement of components may also be necessary to maintain the pump’s performance and prevent damage.

4. Alternative Pump Options:

– If corrosive gases or vapors are involved in the application, it is advisable to consider alternative pump technologies that are specifically designed to handle such substances.

– For corrosive gases, chemical-resistant pumps like diaphragm pumps, peristaltic pumps, or dry screw pumps may be more suitable.

– These pumps are constructed with materials that offer superior resistance to corrosion and can handle a wide range of corrosive substances.

– It is essential to consult the pump manufacturer or a vacuum system specialist to select the appropriate pump for handling corrosive gases or vapors.

In summary, piston vacuum pumps are generally not recommended for handling corrosive gases or vapors due to their construction materials, sealing limitations, and the potential for damage and contamination. It is crucial to choose a pump specifically designed to handle corrosive substances or consider alternative pump technologies that can provide the required chemical resistance and performance.

editor by CX 2023-11-10

China Good quality Oil Free Piston Vacuum Pump Air Compression Pump Small Air Compressor Made in China Silent Oil Pump for Packaging Machinery 850W wholesaler

Product Description

|

Model |

BST850AFZ/BSZ |

|

Voltage/frequency (V/Hz) |

220-240V/50Hz 100v-120v/60Hz |

|

Input power(W) |

≤550 |

|

Speed (r/min) |

≥1350 1650 |

|

Primary vacuumKPa |

-93KPa |

|

Secondary vacuumKPa |

-98KPa |

|

Restart pressure (KPa) |

0KPa |

|

Rated volume flow (m3/h) |

≥12m3/h @0KPa; |

|

Noise dB(A) |

≤62dB(A) |

|

Ambient temperature ºC |

-5-40 ºC |

|

Insulation Class |

F |

|

Cold insulation resistance (MΩ) |

≥100MΩ |

|

Voltage resistance |

1500V/50Hz 1min(No breakdown) |

|

Thermal protector |

Automatic reset 135±5ºC |

|

Capacitance (μF) |

25μF±5% 75μF±5% |

|

Net weight (Kg) |

10.5Kg |

|

Installation Dimensions (mm) |

223.2×88.9 mm(4XM6) |

|

External Dimensions (mm) |

268.8*128*214.7mm |

| Typical application | |

| Respirator (ventilator) | oxygenerator |

| Disinfectant sprayer | Blood analyzer |

| Clinical aspirator | Dialysis / hemodialysis |

| Dental vacuum drying oven | Air suspension system |

| Vending machines / coffee blenders and coffee machines | Massage chair |

| Chromatographic analyzer | Teaching instrument platform |

| On board access control system | Airborne oxygen generator |

Why choose CZPT air compressor

1. It saves 10-30% energy than the air compressor produced by ordinary manufacturers.

2. It is widely used in medical oxygen generator and ventilator .

3. A large number of high-speed train and automobile application cases, supporting – 41 to 70 ºC, 0-6000 CZPT above sea level .

4. Medium and high-end quality, with more than 7000 hours of trouble free operation for conventional products and more than 15000 hours of trouble free operation for high-end products.

5. Simple operation, convenient maintenance and remote guidance.

6. Faster delivery time, generally completed within 25 days within 1000 PCs.

Machine Parts

Name: Motor

Brand: COMBESTAIR

Original: China

1.The coil adopts the fine pure copper enameled wire, and the rotor adopts the famous brand silicon steel sheet such as ZheJiang baosteel.

2.The customer can choose the insulation grade B or F motor according to What he wants.

3.The motor has a built-in thermal protector, which can select external heat sensor.

4.Voltage from AC100V ~120V, 200V ~240V, 50Hz / 60Hz, DC6V~200V optional ; AC motor can choose double voltage double frequency ; DC Motor can choose the control of the infinitely variable speed.

Machine Parts

Name: Bearing

Brand: ERB , CZPT , NSK

Original: China ect.

1.Standard products choose the special bearing ‘ERB’ in oil-free compressor, and the environment temperature tolerance from -50ºC to 180 ºC . Ensure no fault operation for 20,000 hours.

2.Customers can select TPI, NSK and other imported bearings according to the working condition.

Machine Parts

Name: Valve plates

Brand: SANDVIK

Original: Sweden

1.Custom the valve steel of Sweden SANDVIK; Good flexibility and long durability.

2.Thickness from 0.08mm to 1.2mm, suitable for maximum pressure from 0.8 MPa to 1.2 MPa.

Machine Parts

Name: Piston ring

Brand: COMBESTAIR-OEM , Saint-Gobain

Original: China , France

1.Using domestic famous brand–Polytetrafluoroethylene composite material; Wear-resistant high temperature; Ensure more than 10,000 hours of service life.

2.High-end products: you can choose the ST.gobain’s piston ring from the American import.

| serial number |

Code number | Name and specification | Quantity | Material | Note |

| 1 | 212571109 | Fan cover | 2 | Reinforced nylon 1571 | |

| 2 | 212571106 | Left fan | 1 | Reinforced nylon 1571 | |

| 3 | 212571101 | Left box | 1 | Die-cast aluminum alloy YL104 | |

| 4 | 212571301 | Connecting rod | 2 | Die-cast aluminum alloy YL104 | |

| 5 | 212571304 | Piston cup | 2 | PHB filled PTFE | |

| 6 | 212571302 | Clamp | 2 | Die-cast aluminum alloy YL102 | |

| 7 | 7050616 | Screw of cross head | 2 | Carbon structural steel of cold heading | M6•16 |

| 8 | 212571501 | Air cylinder | 2 | Thin wall pipe of aluninun alloy 6A02T4 | |

| 9 | 17103 | Seal ring of Cylinder | 2 | Silicone rubber | |

| 10 | 212571417 | Sealing ring of cylinder cover | 2 | Silicone rubber | |

| 11 | 212571401 | Cylinder head | 2 | Die-cast aluminum alloy YL102 | |

| 12 | 7571525 | Screw of inner hexagon Cylinder head | 12 | M5•25 | |

| 13 | 17113 | Sealing ring of connecting pipe | 4 | Silicong rubber | |

| 14 | 212571801 | Connecting pipe | 2 | Aluminum and aluminum alloy connecting rod LY12 | |

| 15 | 7100406 | Screw of Cross head | 4 | 1Cr13N19 | M4•6 |

| 16 | 212571409 | Limit block | 2 | Die-cast aluminum alloy YL102 | |

| 17 | 000402.2 | Air outlet valve | 2 | 7Cr27 quenching steel belt of The Swedish sandvik | |

| 18 | 212571403 | valve | 2 | Die-cast aluminum alloy YL102 | |

| 19 | 212571404 | Air inlet valve | 2 | 7Cr27 quenching steel belt of The Swedish sandvik | |

| 20 | 212571406 | Metal gasket | 2 | Stainless steel plate of heat and acidresistance | |

| 21 | 212571107 | Right fan | 1 | Reinforced nylon 1571 | |

| 22 | 212571201 | Crank | 2 | Gray castiron H20-40 | |

| 23 | 14040 | Bearing 6006-2Z | 2 | ||

| 24 | 70305 | Tighten screw of inner hexagon flat end | 2 | M8•8 | |

| 25 | 7571520 | Screw of inner hexagon Cylinder head | 2 | M5•20 | |

| 26 | 212571102 | Right box | 1 | Die-cast aluminum alloy YL104 | |

| 27 | 6P-4 | Lead protective ring | 1 | ||

| 28 | 7095712-211 | Hexagon head bolt | 2 | Carbon structural steel of cold heading | M5•152 |

| 29 | 715710-211 | Screw of Cross head | 2 | Carbon structural steel of cold heading | M5•120 |

| 30 | 16602 | Light spring washer | 4 | ø5 | |

| 31 | 212571600 | Stator | 1 | ||

| 32 | 70305 | Lock nut of hexagon flange faces | 2 | ||

| 33 | 212571700 | Rotor | 1 | ||

| 34 | 14032 | Bearing 6203-2Z | 2 |

FAQ

Q1: Are you factory or trade company?

A1: We are factory.

Q2: What the exactly address of your factory?

A2: Our factory is located in Linbei industrial area No.30 HangZhou City of ZHangZhoug Province, China

Q3: Warranty terms of your machine?

A3: Two years warranty for the machine and technical support according to your needs.

Q4: Will you provide some spare parts of the machines?

A4: Yes, of course.

Q5: How long will you take to arrange production?

A5: Generally, 1000 pcs can be delivered within 25 days

Q6: Can you accept OEM orders?

A6: Yes, with professional design team, OEM orders are highly welcome

Q7:Can you accept non-standard customization?

A7:We have the ability to develop new products and can customize, develop and research according to your requirements

| After-sales Service: | Remote Guided Maintenance |

|---|---|

| Warranty: | 2 Years |

| Principle: | Mixed-Flow Compressor |

| Samples: |

US$ 65/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How Does Piston Displacement Affect the Pump’s Performance?

Piston displacement is a crucial factor that significantly affects the performance of a piston vacuum pump. Here’s a detailed explanation:

Piston displacement refers to the volume of gas or air that a piston vacuum pump can move during each stroke of the piston. It determines the pump’s capacity or flow rate, which is the amount of gas that the pump can evacuate per unit of time.

1. Flow Rate:

– The piston displacement directly influences the flow rate of the pump.

– A larger piston displacement corresponds to a higher flow rate, meaning the pump can evacuate a larger volume of gas per unit of time.

– Conversely, a smaller piston displacement results in a lower flow rate.

2. Pumping Speed:

– The pumping speed is a measure of how quickly a vacuum pump can remove gas molecules from a system.

– The piston displacement is directly related to the pumping speed of the pump.

– A larger piston displacement leads to a higher pumping speed, allowing for faster evacuation of the system.

– A smaller piston displacement results in a lower pumping speed, which may require more time to achieve the desired vacuum level.

3. Vacuum Level:

– The piston displacement indirectly affects the achievable vacuum level of the pump.

– A larger piston displacement can help reach lower pressures and achieve a deeper vacuum.

– However, it’s important to note that achieving a deep vacuum also depends on other factors such as the design of the pump, the quality of the seals, and the operating conditions.

4. Power Consumption:

– The piston displacement can impact the power consumption of the pump.

– A larger piston displacement typically requires more power to operate the pump due to the increased volume of gas being moved.

– Conversely, a smaller piston displacement may result in lower power consumption.

5. Size and Weight:

– The piston displacement affects the size and weight of the pump.

– A larger piston displacement generally requires a larger pump size and may increase the weight of the pump.

– On the other hand, a smaller piston displacement can result in a more compact and lightweight pump.

It’s important to select a piston vacuum pump with an appropriate piston displacement based on the specific application requirements.

In summary, the piston displacement of a vacuum pump directly influences its flow rate, pumping speed, achievable vacuum level, power consumption, and size. Understanding the relationship between piston displacement and pump performance is crucial in choosing the right pump for a given application.

What Industries Commonly Rely on Piston Vacuum Pumps?

Various industries rely on piston vacuum pumps for their specific applications and requirements. Here’s a detailed explanation:

1. Manufacturing and Industrial Processes:

– Piston vacuum pumps find extensive use in manufacturing and industrial processes across different sectors.

– They are commonly employed in vacuum packaging, where they help create a vacuum environment to preserve and extend the shelf life of food products.

– In the automotive industry, piston vacuum pumps are utilized in brake booster systems to provide the necessary vacuum for power braking.

– Other industrial applications include vacuum molding, vacuum drying, vacuum distillation, and vacuum filtration.

2. Pharmaceuticals and Medical Industry:

– The pharmaceutical and medical industry extensively relies on piston vacuum pumps for various critical processes.

– These pumps are used in pharmaceutical manufacturing for vacuum drying, solvent recovery, and distillation processes.

– In medical applications, piston vacuum pumps are utilized in vacuum suction devices and medical laboratory equipment.

– They are also employed in vacuum autoclaves for sterilization purposes.

3. Research and Laboratory Settings:

– Piston vacuum pumps are commonly found in research laboratories and scientific facilities.

– They are used for creating vacuum conditions in laboratory equipment such as vacuum ovens, freeze dryers, and vacuum desiccators.

– These pumps are crucial for applications like sample preparation, material testing, and scientific experiments requiring controlled environments.

4. Electronics and Semiconductor Manufacturing:

– The electronics and semiconductor industry heavily relies on piston vacuum pumps for various manufacturing processes.

– They are utilized in vacuum deposition systems for thin film coating, such as physical vapor deposition (PVD) and chemical vapor deposition (CVD).

– Piston pumps are also employed in vacuum furnaces for heat treatment processes in semiconductor fabrication.

– Other applications include vacuum packaging of electronic components and devices.

5. Food Processing and Packaging:

– Piston vacuum pumps play a significant role in the food processing and packaging industry.

– They are used for vacuum packaging of perishable food items, preventing spoilage and extending shelf life.

– In food processing, these pumps assist in vacuum concentration, freeze drying, and deaeration processes.

6. Environmental and Waste Management:

– Piston vacuum pumps find applications in environmental and waste management sectors.

– They are used in vacuum systems for wastewater treatment, including processes like aeration, filtration, and sludge dewatering.

– Piston pumps also assist in industrial and municipal waste management systems for vacuum collection or transfer of waste materials.

7. Other Industries:

– Piston vacuum pumps have diverse applications in additional industries:

– They are used in the glass manufacturing industry for vacuum lifting and handling of glass sheets or products.

– Piston pumps find application in the printing industry for vacuum feeding and ink transfer systems.

– They are employed in the power generation industry for steam condenser evacuation and turbine sealing systems.

In summary, piston vacuum pumps find widespread use in industries such as manufacturing and industrial processes, pharmaceuticals and medical, research and laboratory settings, electronics and semiconductor manufacturing, food processing and packaging, environmental and waste management, as well as in other sectors like glass manufacturing, printing, and power generation.

What Is the Role of Lubrication in Piston Vacuum Pump Operation?

Lubrication plays a crucial role in the operation of a piston vacuum pump. Here’s a detailed explanation:

1. Reduction of Friction:

– Lubrication is essential for reducing friction between moving parts within the pump.

– In a piston vacuum pump, the piston moves up and down inside the cylinder, and lubrication helps to minimize the friction between the piston rings and the cylinder wall.

– By reducing friction, lubrication prevents excessive wear and heat generation, ensuring smooth and efficient operation of the pump.

2. Sealing and Leakage Prevention:

– Lubrication helps to maintain proper sealing between the piston rings and the cylinder wall.

– The lubricating oil forms a thin film between these surfaces, creating a barrier that prevents gas leakage during the compression and vacuum creation process.

– Effective sealing is crucial for maintaining the desired vacuum level and preventing air or gas from entering the pump.

3. Cooling and Heat Dissipation:

– Piston vacuum pumps generate heat during operation, particularly due to the compression of gases.

– Lubricating oil helps in dissipating the heat generated, preventing the pump from overheating.

– The oil absorbs heat from the pump’s internal components and transfers it to the pump’s housing or cooling system.

– Proper cooling and heat dissipation contribute to the pump’s overall performance and prevent damage due to excessive heat buildup.

4. Contaminant Removal:

– Lubrication also aids in removing contaminants or particles that may enter the pump.

– The oil acts as a carrier, trapping and carrying away small particles or debris that could potentially damage the pump’s components.

– The oil passes through filters that help to remove these contaminants, keeping the pump’s internal parts clean and functioning properly.

5. Corrosion Prevention:

– Some lubricating oils contain additives that provide corrosion protection.

– These additives form a protective film on the pump’s internal surfaces, preventing corrosion caused by exposure to moisture or corrosive gases.

– Corrosion prevention is crucial for maintaining the pump’s performance, extending its lifespan, and minimizing the need for repairs or component replacement.

6. Proper Lubrication Selection:

– Selecting the appropriate lubricating oil is essential for the proper functioning of a piston vacuum pump.

– Different pump models and manufacturers may recommend specific oil types or viscosities to ensure optimal performance and longevity.

– It is crucial to follow the manufacturer’s guidelines regarding oil selection, oil level, and oil change intervals.

In summary, lubrication plays a vital role in piston vacuum pump operation by reducing friction, maintaining proper sealing, dissipating heat, removing contaminants, and preventing corrosion. Proper lubrication selection and adherence to manufacturer’s guidelines are crucial for ensuring the pump’s efficient and reliable performance.

editor by CX 2023-11-09

China Air Compressor Pump Head Silent Piston Type Air-compressors 220V 1100W 2hp Oil Free Air Compressor Pump 200lmin @ 3 Bar M3min vacuum pump distributors

Relevant Industries: Lodges, Building Material Outlets, Producing Plant, Equipment Fix Outlets, Foodstuff & Beverage Factory, Farms, Cafe, Property Use, Group3 sort 70004 higher rpm gearbox for agricultural machinery Retail, Foods Store, Printing Retailers, Design works , Strength & Mining, Foodstuff & Beverage Outlets, Other, Advertising and marketing Organization, Common Large Responsibility Villa Entrance Driveway Sliding Gate Wheel Roller Pulley for Observe with UVY Groove One Bearing Dental Clinic and Hospital

Showroom Place: None

Problem: New

Type: PISTON

Configuration: Fashion,Moveable

Power Source: AC Energy

Lubrication Type: Oil-cost-free

Mute: Yes

Design Quantity: JD1100

Voltage: 220V/110V (Tailored)

Dimension(L*W*H): 360*330*330mm

Excess weight: 19KG

Guarantee: 1 12 months

Working Force: 8 bar, .8 bar, 2 bar, 6 bar, Other, 4 bar, 11bar

Air potential: 200L/min @ 3 bar

Machinery Test Report: Provided

Video clip outgoing-inspection: Presented

Advertising Variety: New Merchandise 2571

Warranty of main factors: 1 Year

Main Factors: Motor, Heavy Duty Triple Corner Cable Roller Motor, Pump

Gas Variety: Air

Following-product sales Services Offered: On-line assist

Specification Solution Benefits Firm Profile FAQ Q.1: Query: Is OEM and ODM offered?Don’t fret. We’re glad and welcome to provide the wonderful services for your tailored .Q.2 : May I acquire the sample for tests ?Of program, We are pleased to ship the samples to you. The samples and shipping and delivery freight can be return back again to you with subsequent bulk order .Q.3: What’s the top quality ?Good quality Assurance.We have built strict high quality handle program from product design and style, screening of uncooked supplies and creation to concluded solution in order to ensure the top quality stability of the merchandise.Our principal goal is pursing the greatest high quality.Q.4: How numerous a long time for your guarantee?Warranty is A single many years. We’re please to provide greatest following-sale service, ND A602 Agricultural Corn Harvesters Gearbox guide, totally free spare parts even new product if we can support you to remedy your dilemma.Q.5: Query : How a lot of a long time encounter for generation?Prolonged Historical past. Our manufacturing facility has the production knowledge a lot more than thirteen+ many years. Q.6: How can I talk to a live service and get a quotation?You can deliver us an inquiry by means of Alibaba.

Disadvantages of using a vacuum pump

A vacuum pump is a device that pulls gas molecules out of a volume and leaves a partial vacuum. Its main function is to create a relative vacuum within a given volume. There are several types of vacuum pumps. Some of them are better suited for specific purposes than others. However, there are some disadvantages to using a vacuum pump.

Application of vacuum pump

Vacuum pumps are invaluable tools in many industrial and scientific processes. They are often used to move gas and other harmful substances and to clear clogged drains. They are also used to support mechanical equipment. For example, they can be mounted on the engine of a motor vehicle or the power hydraulic component of an aircraft. No matter how they are used, they should fit the application.

The principle of a vacuum pump is to draw gas from a sealed chamber to create a partial vacuum. Over the years, vacuum pump technology has evolved from its original beginnings to its current form. Today, there are many types of vacuum pumps, including rotary vane pumps, momentum transfer pumps, and regeneration pumps.

The semiconductor industry is a major user of vacuum pumps. Among other applications, these pumps are commonly used for mounting circuit boards, securing components, blowing and jetting, and pumping. The use of renewable resources has paved the way for widespread semiconductor production, where vacuum pumps are crucial. This manufacturing shift is expected to boost vacuum pump sales across Europe.

The most common types of vacuum pumps are positive displacement and rotary vane pumps. Positive displacement pumps are most effective for rough vacuum applications and are usually paired with momentum transfer pumps. These pumps are used in pharmaceutical, food and medical processes. They are also used in diesel engines, hydraulic brakes and sewage systems.

Positive displacement pumps are used to create low vacuum conditions and create a partial vacuum. These pumps create lower air pressure by enlarging the chamber and allowing gas to flow into the chamber. The air in the cavity is then vented to the atmosphere. Alternatively, momentum transfer pumps, also known as molecular pumps, use high-speed rotating blades to create dense fluids.

Their drawbacks

Vacuum pumps are useful in industrial applications. However, they are not perfect and have some drawbacks. One of them is that their output is limited by the vacuum hose. Vacuum hoses are the bottleneck for vacuum pump performance and evacuation rates. The hose must be kept free of water and organic matter to ensure the highest possible vacuum.

Dry vacuum pumps do not have these problems. They may be more cost-effective but will increase maintenance costs. Water consumption is another disadvantage. When pond water is used, the pump puts additional pressure on the treatment facility. Additionally, contaminants from the gas can become trapped in the water, shortening the life of the pump.

Another disadvantage of vacuum pumps is their limited operating time at low vacuum. Therefore, they are only suitable for extremely high vacuum levels. Diaphragm pumps are another option for industrial applications. They have a sealed fluid chamber that allows a moderate vacuum. They also feature short strokes and a low compression ratio, making them quieter than their reciprocating counterparts.

Vacuum pumps are used in many industrial and scientific processes. They can be used to transport hazardous materials or clear clogged drains. They are also used in rear doors and dump tanks. Certain types of vacuum pumps can cause fluid blockages, which can be harmful. The vacuum pump should also be well suited to the fluid in it to avoid contamination.

Another disadvantage is the lack of proper vacuum system testing equipment. Mechanics often underestimate the importance of a properly functioning vacuum system. Most stores lack the equipment needed for proper troubleshooting. Typically, mechanics rely on the cockpit vacuum gauge to determine if the pump is working properly.

Some vacuum pumps are capable of providing constant vacuum. These pumps are also capable of eliminating odors and spills. However, these advantages are outweighed by some disadvantages of vacuum pumps.

editor by czh 2023-02-14

China Rotary Industry Piston Air Compressor Parts

CZPT variety CZPT framework of a unique layout, a compact, fashionable look, large performance, tiny energy use, low sound qualities and extended daily life, is a smart environment-helpful goods. Is widely applied in metallurgy, machinery, substances, and mining, and electric electrical power industries of the perfect fuel supply products.

Advantage:

one.The third generation of superior rotor and concise intake handle program

2.Productive centrifugal separator oil and gasoline, fuel oil content is little,tube and core of long lifestyle .

3. Efficient, lower sounds suction admirer of the entire use of export dynamic pressure

increased influence of heat transfer (air-cooled)

four. CZPT water-cooling system for large CZPT to offer more

efficient

five.Fault diagnosis method, the control panel is simple to operate

six Removable door, tools upkeep, services convenient

seven.Micro-digital processing so that temperature, pressure and other parameters are closely monitored .

Solution HIGHLIGHTS

one.The model electricity,reliable good quality, steady efficiency.The severe thermal equilibrium serviceability can ensure that the device operate efficiently below higher temperature environment (≤40ºC).

2.Special patent design, light-weight load startup program, the air handle design and style is adapt to the drilling function with large steadiness.

3.Successful cooling program, divided into three elements: water- cooled ,mid- chilly, oil cold, which make sure the reputable operation of diesel engine, and it’s ideal for large temperature operating atmosphere.

four.Impartial study and advancement of the opposite door design and style, rational layout, which is simple to do typical maintenace ,with benefits of the set and transportable compressor.

5.A one stage lifting, forklift hole device, geared up with drag ring.It is ideal for fix automobile transportation, straightforward to transfer and set up of the unit.

six.Watertight and dustproof layout, which is ideal for outdoor difficult operating atmosphere.

seven.According to consumer needs, the heating boiler and distant parts is obtainable for cold starting up.

Model CONFIGURATION

Very Successful Two-phase Compression CZPT Airend

High effectiveness two stage compression engine, with super extended bearing existence, high reputable sealing efficiency, made merchandise high quality and manufacturing precision.The extended-phrase marketplace test has set up a good

popularity amid the worldwide customers.

Lengthy running life Low maintenance price

Higher efficiency, tiny leakage triangle, lower specific electrical power

Considerably less put on parts Little vibration, lower noise

Name Model Electricity

CZPT title model diesel engine Low gasoline intake and great gasoline economy

Compact framework is straightforward to be maintained Super energy,eco-friendly and enviromental safety

Xihu (West Lake) Dis.nized Handle Technique

German model VDO instrument Clear speak to surface ,effortless operation

Large performance, manufacturer guarantee CZPT powerful sensitivity

Air Program- Over Loading Air CZPT

CZPT States model reloading air filtration, cyclone filtration and adsorption filtration, double filtration impact

Dust removing ≥99.nine%,filtering fineness ≤3μm

Making certain the airend to be effectively dustproof and the top quality of the air.

Software fields

Comps two-stage compression diesel fastened screw CZPT is extensively utilised in

Our Exhibition

1.Pre-sale service:

Act as a good adviser and assistant of clientele allow them to get abundant and generous returns on their investments . 1.Pick products product. two.Style and manufacture goods in accordance to client’s unique prerequisite 3.Practice technical personnel for consumers .

two.Companies throughout the sale:

1.Pre-verify and settle for products ahead of shipping and delivery .

two. Help clientele to draft resolving programs .

3.Following-sale solutions:

Give considerate providers to minimize clients’ worries.

one.CZPT Following-product sales support,expert engineers available to support equipment at house or oversea.

two. 24 several hours technological support by e-mail.

3.Other crucial technological support.

Parts AC High Pressure Screw Portable Rotary Piston Samsung Air Pump Compressors Compressor

|

Electrical power: |

750w |

Voltage: |

220V |

|

Exhaust Strain: |

.8Mpa |

Present: |

seven.5A |

|

Frequency: |

50HZ |

Revolving Pace: |

2850rpm |

|

Quantity of Gasoline Storage Tank: |

9L |

Cylinder: |

42mm |

Mini Industrial Used Portable High Pressure Oilless Screw Part Parts Free Rotary Piston Single Movable Max Dental AC Oil Air Pump Compressor Compressors

Oilless Air CZPT Featuers:

1.Tremendous Silent

Tremendous lower sounds.The output air force is steady with no fluctuations, reducing noise pollution.

2. Safety

If the voltage or existing lead to the device overheat, it will routinely shut down to safeguard from burnout.

3. CZPT management

Pressure swap automatically controls the start and end of the machine.

4. Adjustable air force

The air force can be modified to meet up with the requirements of different equipment usage.

5. Help save human power

Swap on the CZPT can work generally & automatically. It is straightforward to operate and does not want human to be on responsibility.

6. Effortless maintenance

No require to incorporate any lubricant, effortless maintenance right after obtain.

Elements Features

1.Weighty cast iron physique: large load, extended stroke, minimal gasoline consumption, low sounds

two.Cylinder: made of large-quality forged iron, toughness, good lubricity, wall by the fantastic honing, use-resistant, durable

three.Piston ring: excellent elasticity, excellent use resistance, minimal oil intake, not straightforward to make the valve team carbon deposition and reduction of oil to burn off the crankshaft and connecting rod.

4.The crankshaft, connecting rod, piston: properly balanced, put on resistance, substantial power, easy working equilibrium.

five.Large reputable and tough valve strong aluminum alloy physique, mild and warmth.

six.The motor provides reliable power, minimal voltage start up and working performance powerful fan cooled motor and entire body particular shock proof style.

7.Double nozzles, had been used to immediate the exhaust and pressure exhaust force switch with push button, secure and handy

8.Oil cost-free,silent,defend-environment,suitable for dental use.

Frequency Asked CZPTion

one.Are you the producer or investing company?

We are the manufacturer.

two.The place is your manufacturing unit?

It is located in HangZhou City,ZHangZhoug CZPT,China.

three.What’s the conditions of trade?

FOB,CFR,CIF or EXW are all appropriate.

four.What is actually the phrases of payment?

T/T,L/C at sight or money.

5.What is actually the guide time?

We are the manufacturer.

It is located in HangZhou City,ZHangZhoug CZPT,China.

FOB,CFR,CIF or EXW are all appropriate.

T/T,L/C at sight or money.

In 15 days on receipt of deposit .

six.Do you acknowledge sample buy?

Yes,we take.

seven.What about the value of sample?

You have to pay the freight cost.But the value of item could be refundable,if you will buy 1x20GP container in the long term.

Yes,we take.

You have to pay the freight cost.But the value of item could be refundable,if you will buy 1x20GP container in the long term.

Dental Max Movable Single Mini Used AC Oil Rotary Industrial Portable High Pressure Oilless Screw Part Parts Piston Free Air Pump Compressors Compressor

| Energy: | 550w | Voltage: | 230V |

| Exhaust Force: | .8Mpa | Present: | three.3A |

| Frequency: | 50HZ | Revolving Pace: | 1420rpm |

| Volume of Fuel Storage Tank: | 24L | Cylinder: | 2x55mm |

Oilless Air CZPT Featuers:

1.Tremendous Silent

Tremendous lower sounds.The output air stress is stable with no fluctuations, decreasing sound air pollution.

2. Basic safety

If the voltage or recent trigger the device overheat, it will immediately shut down to safeguard from burnout.

3. CZPT handle

Pressure switch immediately controls the begin and stop of the equipment.

four. Adjustable air strain

The air strain can be modified to satisfy the wants of various equipment usage.

5. Help save human power

Switch on the CZPT can perform typically & automatically. It is easy to work and does not want human to be on obligation.

6. Effortless routine maintenance

No want to incorporate any lubricant, simple upkeep after buy.

Parts Features

1.Hefty cast iron entire body: heavy load, prolonged stroke, reduced gas use, reduced noise

2.Cylinder: made of high-grade forged iron, power, great lubricity, wall by the good honing, dress in-resistant, resilient